Rotary Slotter Machine

Rotary Slotter Machine

Product Description

Imported Rotary Slotter Machine:

1. Creasing dies,

2. Cutting Dies (Half Round model),

3. Slotting dies

4. Corner cutting Die

With electric phase adjustment, only 3 HP AC Motor and variable speed AC Drive, counter, Combined movement of both Slotting Dies and Creasing Dies, Brass Waste Remover complete with all standard accessories and electricals.

Specification :

Speed : 60 Pcs Per Minute

Motor Power 5 kw

Voltage 440 V

Quantity 1 Unit

Window Patching Machine

Window Patching Machine

Description

Applicable to PET, PVC, PP, OPP, PE, or even paper, also applicable to plastic film with special effects, for example, shiny film, matt film, a flash film, colored film, printed film, UV filtered film and fluorescent film.

Special Features

1. Full servo feeder and convey system

2. Full servo gluing system

3. Creasing and notching section

4. Full servo window pasting unit

5. Automatic delivery unit

Specification :

Accuracy +- 1mm

Machine Weight - 3300 kg

Motor Power - 3 kw

Quantity - 1 Unit

Six Col. Komori Printing Machine

Six Col. Komori Printing Machine

Product Description :-

1. Komori Lithrone 640 LX

2. Six Color with Coater Straight Offset Printing Machine

3. Printing Sheet Size: 28" x 40"

4. Auto Make Ready (AMR)

5. Hard Chrome Cylinders

6. PQC with Plate Cocking

7. Komorimatic Damp

8. Quick Action Plate Clamps (QAPC)

Specifications :

Brand - Komori Lithrone 640 LX

Machine Type - Offset Printing Machine

One Time Printing - Six Colour with Coater

Quantity - 1 Unit

Double Joint Flap Pasting Machine

Double Joint Flap Pasting Machine

Heavy duty standard model semi auto Double Joint flap pasting machine with all standard accessories.

Function :

1. The machine can glue the opening of 3-ply and 5-ply corrugated cardboard.

2. Low-cost machine, suitable for all kinds of cartons.

3. Auto piler allows to load maximum carton to operate.

4. Quick change over of sizes.

5. Continuous carton feeding is possible.

6. Automatic digital counter.

7. Finished carton travels to the end of conveyer by setting the number of cartons as per requirement.

8. Reduces manpower while comparing manual method. Strong bonding and even pressing of the carton.

Specification :

Capacity -box per hour

Phase - 3 Phase

Motor Horsepower - 2hp

Quantity -1 Unit

Side Flap & Lock Bottom Pasting Machine

Side Flap & Lock Bottom Pasting Machine

Side Flap & Lock Bottom Pasting Machine

Use and characteristics:

Pre fold crash lock bottom folder gluer, also known as pre-fold lock-bottom high-speed automatic pasting machine, is a newly designed equipment which comes with high speed, pretty surface and simple operation. It is both economical and practical. Therefore, our equipment is widely employed for pasting lock-bottom or non-lock-bottom boxes.

Specification :

Machine Type - Automatically and continuously feeding.

Linear velocity - 0 ~ 220m /min

Paste box basic form - One-side edge pastes, two-side edge pastes.

Quantity- 1 Unit

Moisture Controlling Machine / BS Testing Machine

Moisture Controlling Machine / BS Testing Machine

Usage:

It is used to find the percentage of water in the given substance. It gives accurate results when any substance is tested. Our range is mostly used for paper boards, corrugated stock and paper tubes.

Specification -

Moisture Range - 0-60%

Operating Temperature -10 to 60 Degree Celsius

Usage/Applicable on Moisture Detection

Quantity 1 Unit

Side Flap for Fold Pasting Machine

Side Flap for Fold Pasting Machine

Side Flap for Fold Pasting Machine

Use and characteristics:

Automatic folder gluer machine consists of three sections: vacuum feeding section glue and folding section, counter, and stacker section.

Frequency conversion motor with quality inverter adjust speed. PLC and touch screen control system for easy operation and running stable. Average speed 150 sheets/min. energy conservation and high speed.

Specification :

Machine Type - Fully-Automatic

Phase - Three

Power Source - Electric

Quantity - 1 Unit

Side Flap Semi Automatic

Side Flap Semi Automatic

Side Pasting Machine is designed to finish the box making process easily and fast. The machine has a variable speed motor with suction feed to adjust the quantity of the boards.

Folding Gluing, Pasting, Aligning, Counting, and Delivery are the function of the machine. Semi-Automatic Corrugated box flap pasting is designed to finish the box making process easy and fast.

Indian ABB AC motor, VFD ABB AC Drive used for power saving. Feeding is to be done manually, Gluing, Pasting, Aligning, Pressing, Counting and Ejecting as per batch set, are done automatically Avoid Rust on the top of Box, Increase Production and Quality of box.

Specification :

Machine Type - Semi-Automatic

Phase - Three

Power Source - Electric

Quantity – 1 Unit

Thermal Lamination Machine

Thermal Lamination Machine

We are using fluid heat control system with digitally heat controlling unit to provide our customers with the best result from our machine.In this machine pre-gummed film is used when it passes from digitally heated roller gum melts and film is laminated on the paper to provide the finest results. This film is in turn applied to a substrate such as paper or card using pressure rollers. The primary purpose of lamination with such a machine is to embellish or protect printed documents or images.

Salient Features:

Single side laminator as well as Both sided laminate

Temperature Control

Digital sheet counter

Equipped with cooling fans

Hand-held cutter quickly separates laminated sheets.

Specification :

Machine Size - 712MM

Lamination Speed - 0-25m/min

Power - 0.75KW

Quantity - 1 Unit

Lamination Machine

Lamination Machine

Paper Lamination Machine is specially designed to meet generally demand of film lamination jobs, examples like poster, greeting cards, book titles, cardboard, cartons, folding boxes etc

Salient Features:

Provision for Roll-to-Roll lamination.

Extended Feeding Table.

Variable Speed Drive Controls.

Film Slitting Attachment.

Wrinkle Free Lamination of Film.

Machine is also suitable for strip lamination.

Hard Chrome Rollers.

Specification:

Machine Size - 864 MM & 1016 MM

Laminating Speed - 0-25m/min

Power - 0.75KW

Quantity - 2 Unit

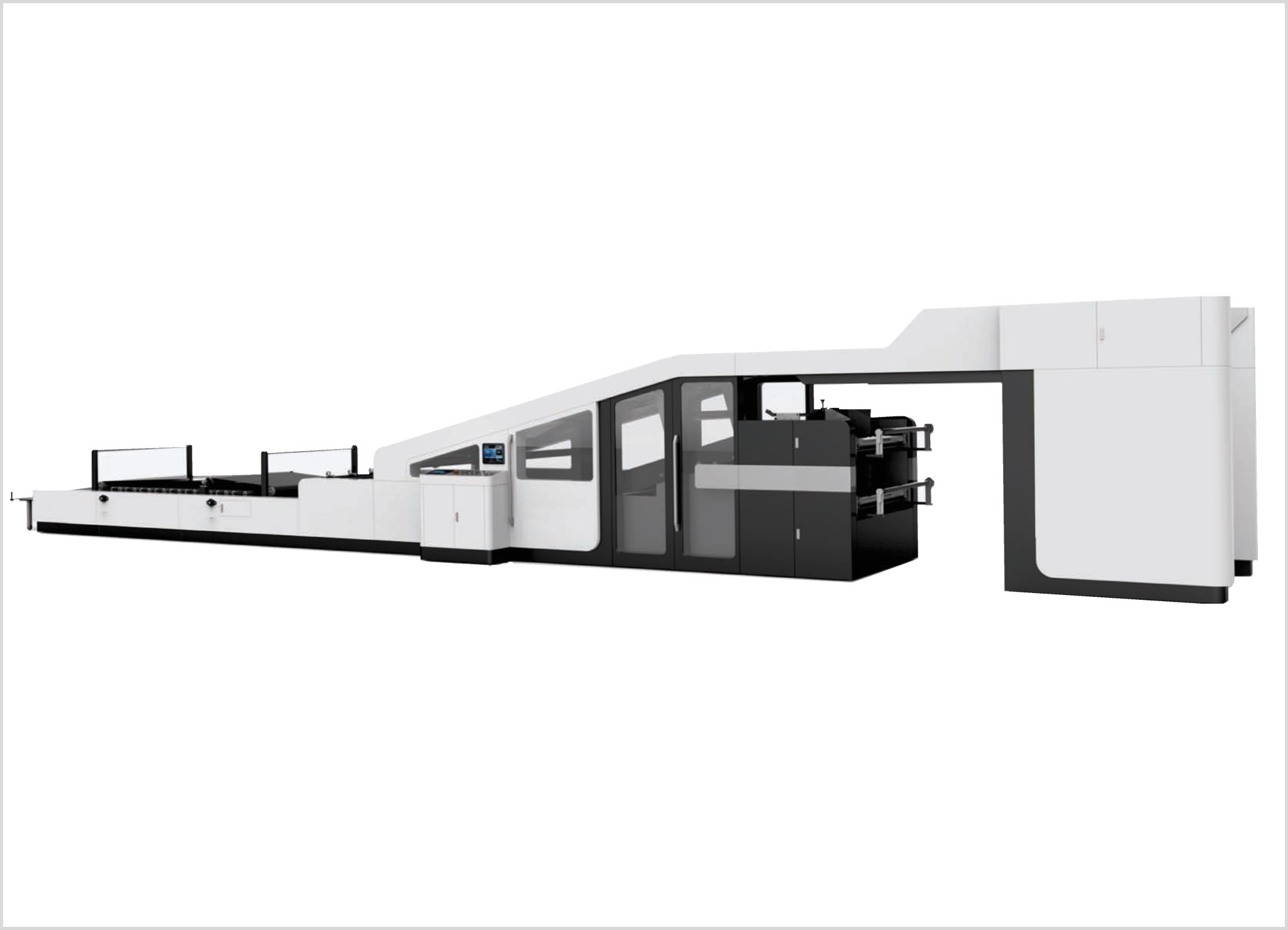

Automatic Die Cutting

Automatic Die Cutting

Automatic Die Cutting and Creasing Machine (WITH/WITHOUT STRIPPER)

1. The perfect solution for boards and 3-ply corrugated sheets.

2. To improve the machine's productivity, we provide a pre-loader to accommodate twice the paper load, a variable-speed paper feeding structure, an auto paper-collecting structure, a pneumatic sampling mechanism, auto-timing oil lubrication, and forced air cooling for the main drive's lubricating devices for this machine.

3. It's suitable for die-cutting and embossing paper, paperboards, and multi-flute cartons.

Specification :

Max Paper Size : 737 x 1041 MM

Corrugated Paper : < 6 MM

Max Die Cutting Speed : 5000 Speed/hr

Power : 15 KW

Quantity : 1 Unit

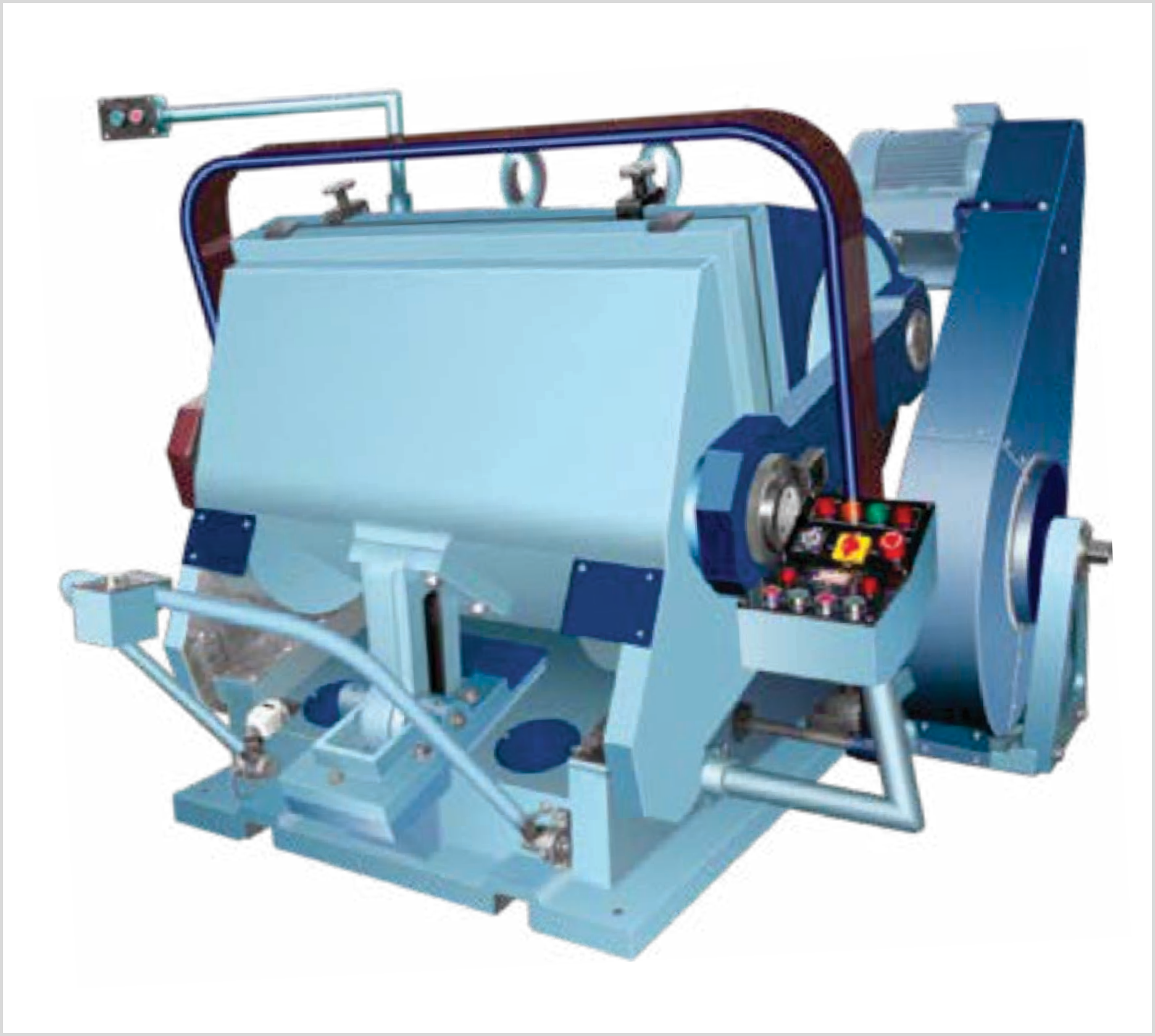

Manual Die Cutter

Manual Die Cutter

Platen Die Punching is designed for heavy-duty tasks of cutting, creasing, and embossing paper, linoleum, cardboard, corrugated board, plastic, PVC material, and more.

The machine is equipped with an Electro-magnetic Clutch & Brake, Dwell Timing Device, Electric Impression Counter, safety guards for the operator's safety, as well as circuit locking and a circuit breaker.

Laminator

Laminator

Fully Automatic 5 Ply Flute Laminator is composed of face paper auto rising structure, face paper delivery, double bottom paper delivery synchronously and asynchronously, double bottom paper positioning structure, coating circularly structure. face and bottom paper positioning pressing structure and auto collecting structure.Itcanfinish high precisionhigh speed laminating of colour face paper and cardboard above 350g and corrugated board. It is the most ideal laminating equipment of packagingindustries at home and abroad.

Specification :

Max Sheet Size : 3 PLY 1667 X 1143 MM | 5 PLY 1219 X 1219 MM

Max/Min Weight of Paper : 150 gsm/ 800 gsm

Thickness of Paper : 0.5 - 10 MM

Paperboard & Corrugated Board : 1.5MM

Machine Speed : 5000 sheet / hour

Total Power : 28Hp

Single Facer Corrugation

Single Facer Corrugation

To form or shape into wrinkles or folds or alternating ridges and grooves is corrugation.

A corrugator is a set of machines designed to bring together three, five and seven sheets of paper to form single, double, and triple wallboard in a contiguous process.

The corrugator takes large rolls of paper produced on paper machines. flutes the medium and glues it to the liners, one at a time, and delivers stacked, cut, and scored sheets of corrugated board to various converting machines.

Specification :

Size | Flute

36'' Fingerless - C Flute

42'' Fingerless - N Flute, C Flute, E Flute

Quantity - 4 Units

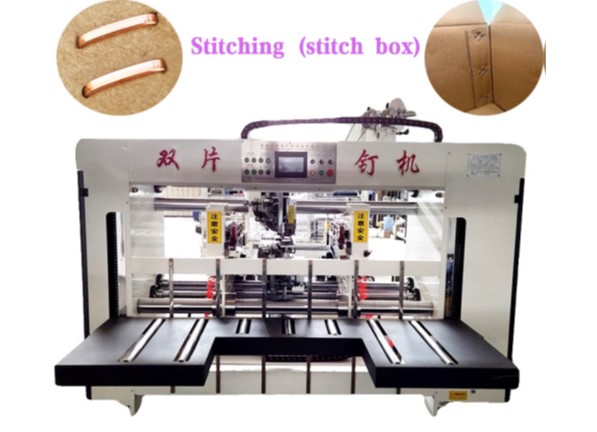

Box Stitching Machine

Box Stitching Machine

Imported four-servo control system. One set of dual purpose can nail single, double, and irregular cartons. The size adopts all-electric control Can be nailed: single nail, double nail and reinforced nail can be completed at one time. The paper feeding section automatically counts, and the finished product is sent out for bundling. Suitable for small and medium-sized cartons, fast binding, and labour-saving.

Adjust the nail distance, use the computer to set the nail distance automatically. It is suitable for small and medium-sized cartons with three or five layers. The cartons with a bottom and no lid can also be nailed, and the seven layers need to be customized.

The nail distance (small-large) 30mm- 120mm can be adjusted arbitrarily. Mechanical speed: 500 nails/min.

© Copyright 2023. All Rights Reserved.